The Group has invested 4.5 million euros in biosecurity solutions in its poultry companies in Latvia.

The Group has invested 4.5 million euros in biosecurity solutions in its poultry companies in Latvia.

In 2020, the poultry company Putnu Fabrika Kekava, which is well known to Lithuanian consumers, standalone invested more than 1.3 million euros in technologies and procedures ensuring the highest biosafety standards, over 500 thousand euros were invested into feedstuffs heat treatment equipment. And the total investment in biosecurity measures in poultry farms has reached EUR 4.5 million already over the last several years.

‘Over the last six years, we have been making intensive investments to improve the bird living conditions, enhance biosafety and have more sustainable production. This has already brought a visible and sustainable result: since January 2020, we have been raising all broilers without the use of antibiotics. In 2016, we started antibiotic-free raising of broilers in some poultry houses, and within 4 years became totally antibiotic-free. To achieve this, we have paid special attention and directed investments to improve biosafety. With the rampant highly pathogenic avian influenza in Europe, which is also being reported in Latvia, our decision looks very timely. Human safety is also one of the most important issues, especially when we still have to fight the Covid-19 pandemic’, says Andrius Pranckevičius, Chairman of the Board of AS Putnu Fabrika Kekava.

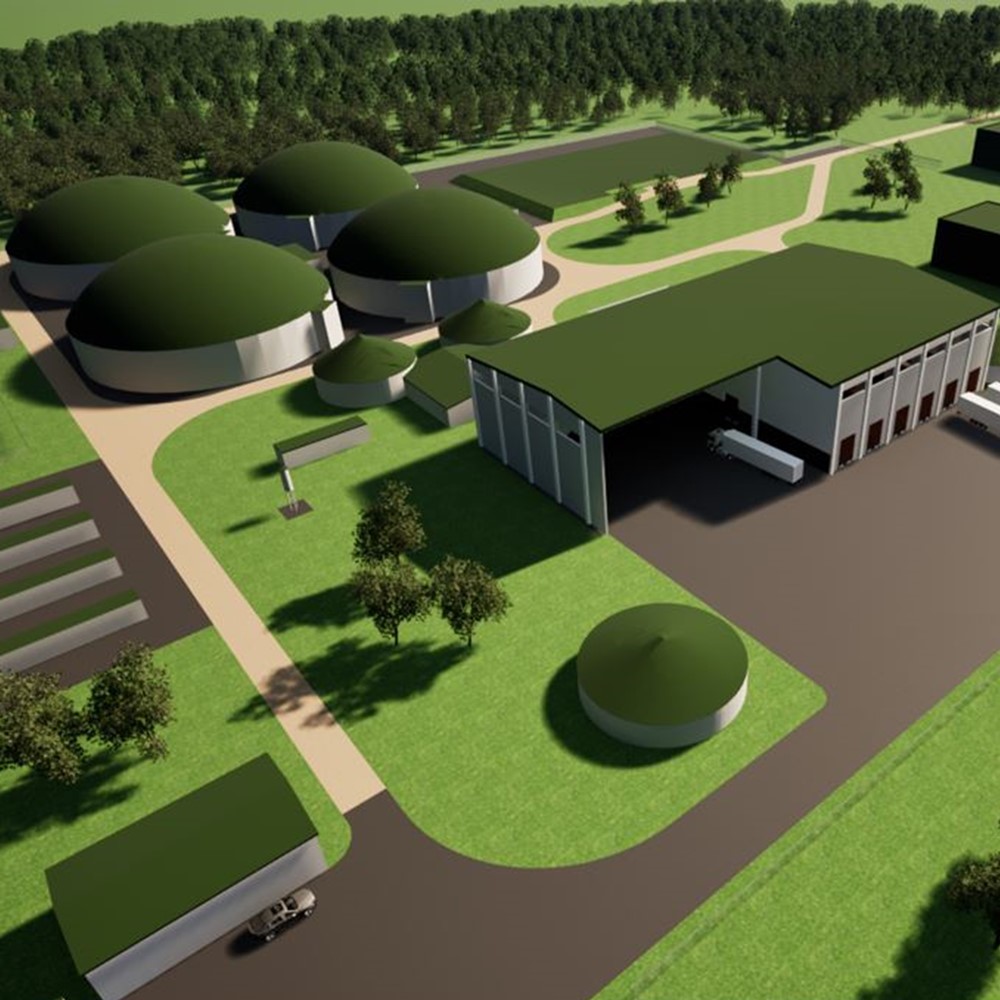

Most of the investments in the Linas Agro Group’s poultry farms in Latvia were allocated for the installation of disinfection barriers and feed treatment equipment. The poultry farms operating in Kekava and Bauska have installed disinfection gates for heavy transport, which is being disinfected before entering the territory of the poultry farms, as well as disinfection barriers for people entering the premises. These measures help to reduce the penetration of any virus and other infectious diseases into production facilities.

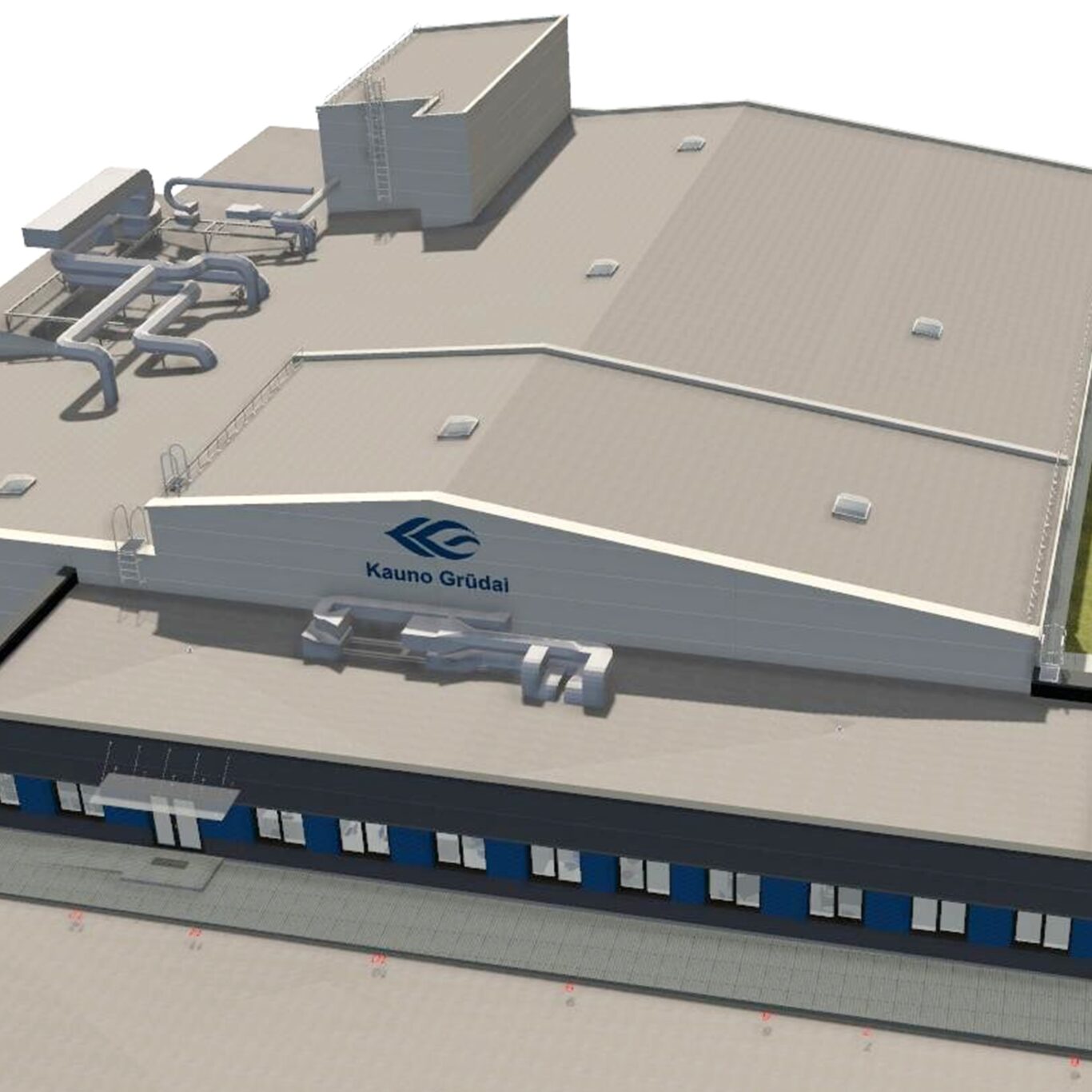

A modern heat treatment system for feedstuff, that cost over 0.5 million euros, works in a similar way like milk pasteurization process: feedstuffs or feed pellets are treated for a certain time at high temperatures, killing harmful micro-organisms and potential pathogens, but preserving the necessary vitamins and minerals.

‘This technology reduces the risk of various diseases, including avian influenza, which is currently at a critical level. Moreover, to protect both birds and workers, we use severe biosecurity procedures, which we have been following for almost 1.5 years. We can state that there is a military readiness in our poultry farms, and the order is no less strict than in the military forces,” says A. Pranckevičius.

The poultry companies owned by AB Linas Agro Group employ 1,100 people in Latvia and have full poultry production cycle: from chicken hatching, rearing, production of poultry feed to production of poultry products. In 2016, AS Putnu Fabrika Kekava was the first in the Baltic region and one of the few in Europe to succeed in implementing a production model that ensures a healthy poultry raising process without the use of antibiotics. About 50 percent the company’s poultry products are being exported – most of the exports go to Sweden.